Threat Roundup for August 14 to August 21

August 23, 2020

How SMBs Are Reacting to a New Way of Working

August 25, 2020Autodesk PowerMill, PowerShape and PowerInspect Join Fusion 360 Family, Better Uniting Manufacturing and Design

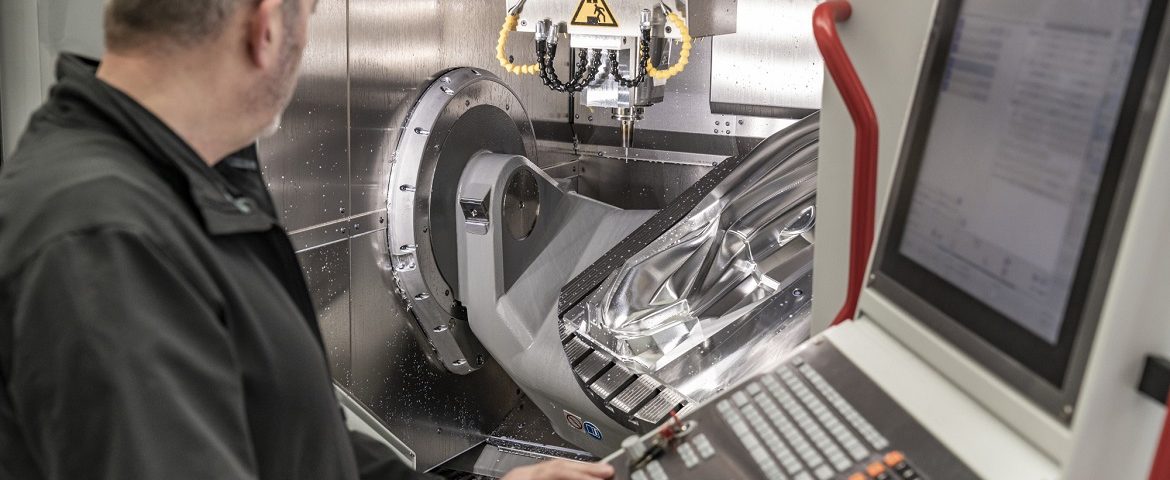

A leading global manufacturer of precision milling machines, Hermle AG uses Autodesk PowerMill to create complex, high-performance equipment.

In September, Autodesk is taking another step to bring design and manufacturing closer together with PowerMill, PowerShape, and PowerInspect joining the Fusion 360 family of solutions. Subscribers will continue to have access to the same advanced manufacturing capabilities of PowerMill, PowerShape, and PowerInspect that they have today. In addition, they will now be able to also take advantage of the next-generation, cloud-based design and manufacturing technology offered in Fusion 360, Fusion 360 Team, and the exciting new Fusion 360 Machining and Fusion 360 Additive Build extensions coming in October.

In fact, in most cases subscribers will receive access to a broader range of functionality at a lower price. For example, current PowerMill Premium subscribers will upgrade to the new “Fusion 360 with PowerMill Ultimate” package, which includes access to the Fusion 360 Machining and Additive Build extensions.

Our intent with this transition is to future-proof our customers’ design and manufacturing processes, empowering them to work in new, more efficient ways to gain competitive advantage.

This is a key step toward Autodesk’s long-standing vision of catalyzing seamless collaboration between designers and engineers, improving manufacturers’ ability to connect workflows, automate processes, and network with supply chains. By uniting technologies under the power of a single platform, Fusion 360 enables a cohesive experience across design, engineering, and manufacturing with data at the center. This single platform then makes it easy to experiment with transformational new tools for design automation, such as the generative design extension we recently announced.

Motorcycle parts manufacturer MJK Performance uses the generative design capabilities in Autodesk Fusion 360 to create multiple designs and more easily assess the tradeoffs of using different materials and manufacturing methods.

“These solutions give us a lot of flexibility in terms of improving automation,” says David Krajci, Chief Operating Officer of 3-Dimensional Services Group, which decreased time from design to shop floor by as much as 40 percent when asked by Kia Motors Manufacturing Georgia to quickly produce face-shield headbands for COVID-19 healthcare workers. “The most important thing we learned on this project is that anything is possible when teammates are fully aligned,” he said.

“With the variety of software that Autodesk has, we can use PowerMill, PowerShape and Fusion 360, and all our tools are in one toolbox,” said Anthony Wooten, CNC machinist at Precise Tooling Solutions. “We chose PowerMill because it doesn’t limit us with defined CAM cycles—you’re able to manipulate and do editing all on the fly. I like to use the term ‘it’s without walls.’” Wooten described Precise Tooling’s workflow of auto-generating tool paths by seamlessly passing files from PowerMill to PowerShape as “a hundred percent human-error-free.”

“Designers and engineers who use Fusion 360 already have the industry’s most capable cloud-based manufacturing platform available at their fingertips,” said Stephen Hooper, vice president and general manager of Fusion 360. “With this change to how we provide access to Autodesk’s advanced manufacturing specialty software, we’re raising that bar, enabling teams to include, and in some cases explore for the first time, even more modern capabilities in their workflows.”

Learn more about this and other Autodesk news during the Advanced Manufacturing Summit virtual event, August 25th starting at 8:00am (Pacific Time) with a keynote from Srinath Jonnalagadda, Autodesk Vice President of Business Strategy for Design & Manufacturing.