Google – Technology Integrations

December 8, 2019

Surface Laptop 3 and Surface Pro 7 now available in Malaysia

December 10, 2019We’re Tipping Our Hats to These Manufacturing Customers for Their Inspiration and Innovation

Here at Autodesk, we’re continually amazed by the many companies who are leading and transforming design and manufacturing processes in a positive way, and we recently honored several companies for their achievements at the third annual Design & Manufacturing Excellence Awards, held at Autodesk University in Las Vegas.

Read how these inspiring teams are tapping into the power of new technology and pushing the boundaries of innovation:

Category: Innovator of the Year

Winner: Volkswagen Group of America

To celebrate the 20-year anniversary of its largest vehicle research facility outside of Germany, the team at Volkswagen’s Innovation and Engineering Center reimagined the VW bus — an iconic symbol of the company’s heritage and values.

With a focus on maximizing strength while minimizing weight, the VW team collaborated with Autodesk by applying generative design to the wheels to reduce the overall weight and rolling resistance on the tires.

Meet the designers who created the VW Type 20 Bus.

The new wheels are 18 percent lighter than a standard set, and the overall development time from design to manufacture was cut from 1.5 years to a matter of months.

Generative design was also used to reconceptualize the steering wheel, as well as the support structure for the rear bench seating and the external side mirror mounts.

The Type 20 electric-infused showcase vehicle combines classic Volkswagen design with new technologies that are shaping the future of the automotive industry.

Using Fusion 360, the VW team rapidly developed options for reducing mass in the wheels while exploring multiple manufacturing methods.

Category: Industry Disruptor

Winner: Airbus

Innovators at Airbus headquarters in Germany are pushing the boundaries of generative design technology to change the way things are manufactured and built in the aerospace industry.

The team continues to make advances with its Bionic Partition project. Using new constraints made available in generative design technology, Airbus optimized a new partition that is significantly lighter, yet just as strong, and can be manufactured at a fraction of the cost using a casting process.

Read more about how generative design is transforming the way we make things.

In addition, the team is applying generative design to other structural aircraft components such as the vertical tail plane of its A320 aircraft, targeting mass, stiffness, and impact resistance.

Finally, Airbus innovators are looking into generative design for the layout of a new production facility that meets the highest standards for sustainability, and ultimately enables its workforce to assemble engines more quickly with more efficient logistical flows.

Bastian Schaefer, Innovation Manager for Airbus Operations GmbH, unveils the original bionic partition.

Category: Engineering the Impossible

Winner: Dynamic Attractions

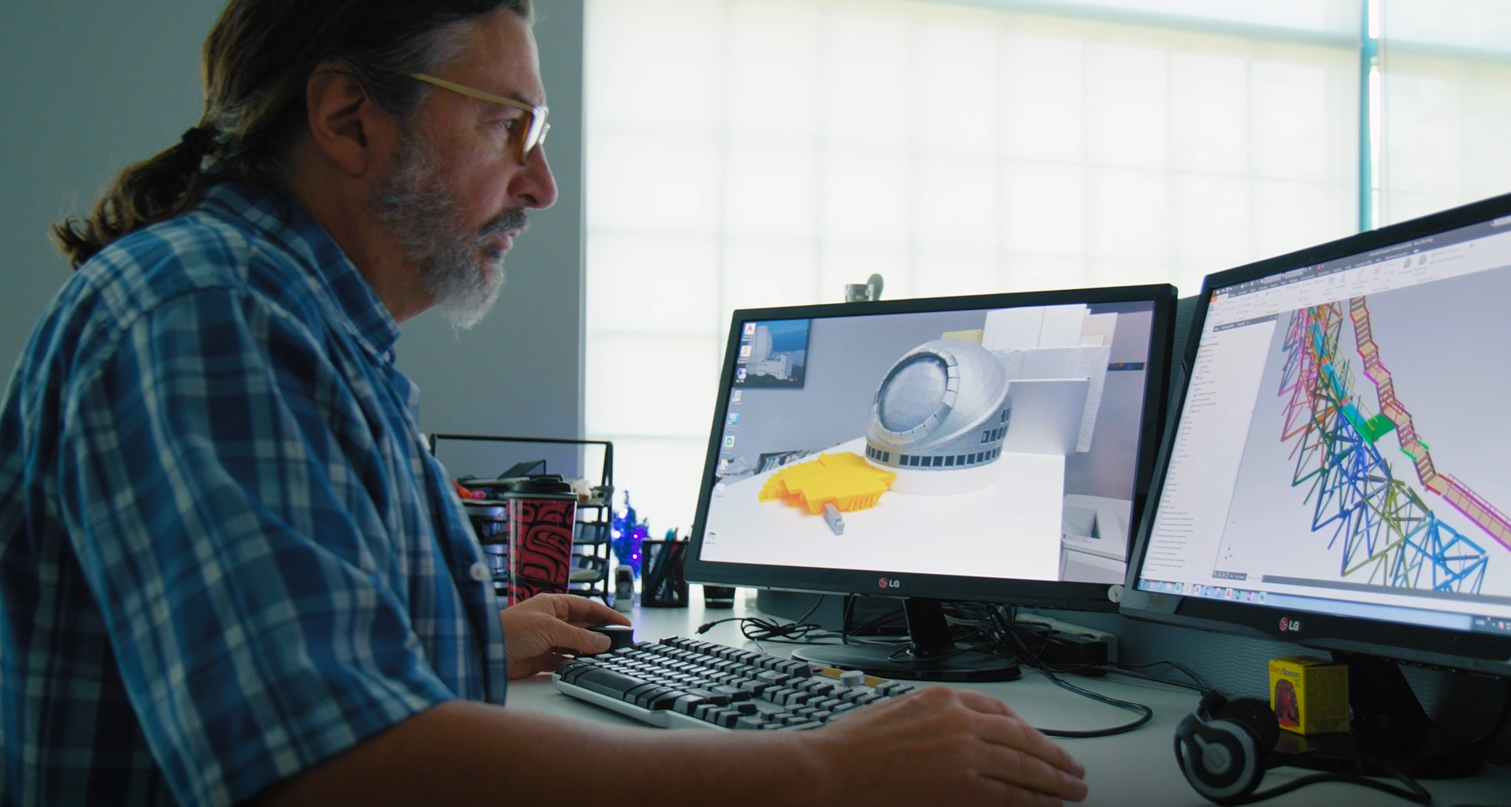

Dynamic Attractions is pushing the boundaries of design and manufacturing.

From complex bridges — to observatories that house the world’s largest telescopes — to thrilling theme park rides, this century-old company has rightfully earned the award for “Engineering the Impossible.”

Using tools in the Product Design & Manufacturing Collection to create cutting-edge designs, enhance workflows, and increase productivity, Dynamic Attractions’ engineers are the secret ingredient behind numerous award-winning projects.

With a reputation for ground-breaking innovation, Dynamic Attractions is staying true to its motto, “Anything you can dream, we can build.”

Dynamic Attractions’ engineers design and erect some of the most complex structures imaginable.

Category: Industry Collaboration

Winner: LASIMM

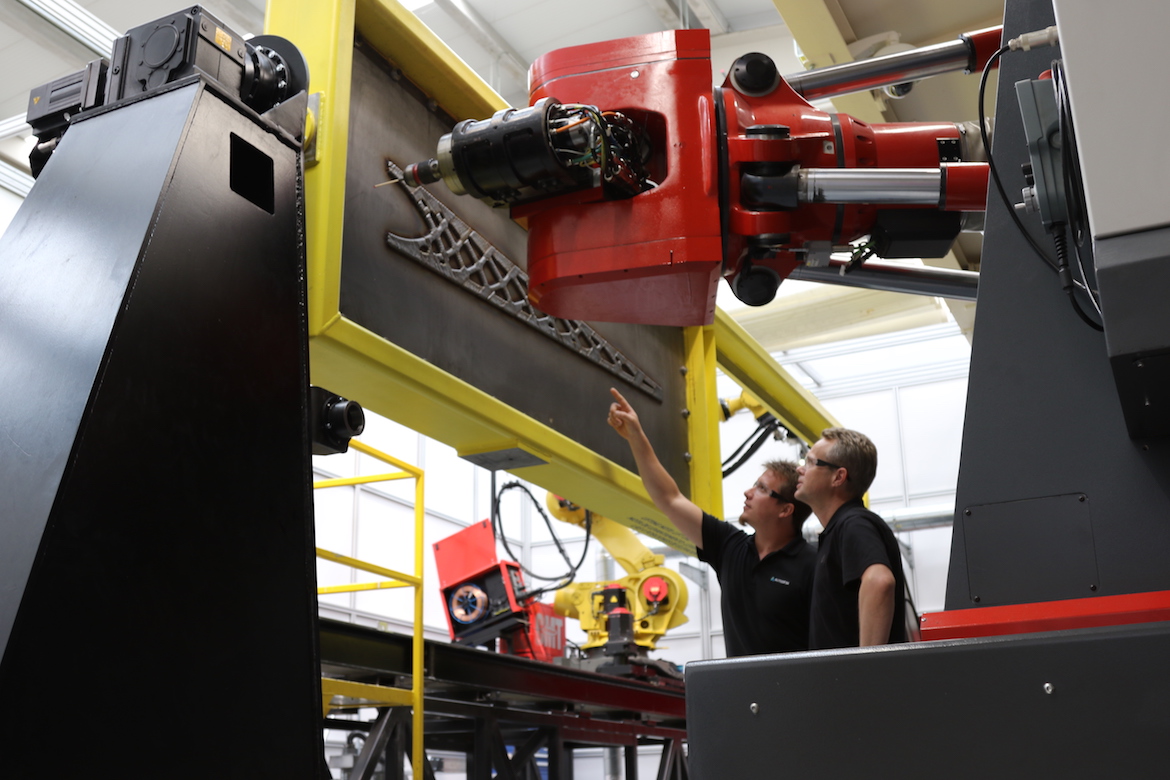

Paving the way for giant metal parts and structures to be 3d printed for construction, the Large Additive Subtractive Integrated Modular Machine (LASIMM) is a groundbreaking project led by 10 partners from across Europe. Its goal is to build one of the world’s largest hybrid manufacturing machines.

The LASIMM machine features unique metal additive and subtractive capabilities, with abilities to 3D print metal parts and structures as large as 20 feet by 6 feet, and up to 4500 pounds.

The machine was recently tested to manufacture demo parts, such as large beam structures, airplane panels, and wind turbine parts, designed by leading industrial end-users including Foster & Partners.

Powered by Autodesk Fusion 360 and Autodesk PowerMill, the LASIMM project brings hybrid manufacturing to a truly global and industrial scale.

LASIMM provides additive and subtractive capability that, in some cases, can lead to major cost and production savings compared to multiple separate machines.

Category: Making a Better World

Winner: KickStart International

Africa is a continent with a large population of farmers who are struggling to feed their communities, even though it holds more than one-quarter of the world’s arable land. This challenge contributes to rampant poverty, malnutrition, and unfortunate yet avoidable health and education outcomes.

KickStart International is a non-profit social enterprise focused on lifting millions of African farmers out of poverty.

Meet the Autodesk Foundation and its grantees.

By designing low-cost, high-quality irrigation pumps, KickStart makes irrigation affordable by significantly increasing crop yields, incomes, and helping farmers establish profitable businesses.

Through a partnership with the Autodesk Foundation, Kickstart recently finalized key design elements for its MoneyMaker Solar Pump. Designed using Autodesk Fusion 360, the pump is currently being tested in Kenya, and is the lowest cost solar pump available in Africa.

Since inception, KickStart has sold more than 330,000 irrigation pumps, created a quarter million businesses, and has helped nearly 1.5 million people out of poverty.